SAM Controllers

SAM CAN Bus Wiring Tester - Find Bad CAN Wires, Connectors & Shorts the Easy Way

SAM CAN Bus Wiring Tester - Find Bad CAN Wires, Connectors & Shorts the Easy Way

Low stock: 2 left

SKU:SAM-CWT4510X-D

Couldn't load pickup availability

The Problem Every Technician Knows Too Well

Your scan tool shows U0100, U0073, and a dozen other communication codes. You clear them. They come back. You check modules... they're fine. You swap the ECM, and $900 later, same codes.

The problem? A mouse chewed 90% through the insulation. Or a connector pin has corrosion. Or the CAN wires are intermittently touching inside the harness wrap.

Traditional scan tools can't see this. Oscilloscopes can but require training and interpreting complex waveforms. This tester just gives you the answer.

What This Tester Actually Does:

Put It In The Loop - It Talks AND Listens

Connect this tester anywhere in your CAN network at the OBD-II port, directly on module connectors, or spliced into bare wires. It actively transmits real CAN bus data packets while simultaneously monitoring voltage levels on both CAN_H and CAN_L lines. It compares what it sent versus what actually came through the wire.

The result? You can pinpoint and locate exactly where the problem is and identify which module, connector or wire is faulty all without firing the parts cannon.

Detects 6 Critical Wire & Connector Faults:

- Code 0: All Tests Pass - Wiring is healthy, ~60Ω resistance, proper voltage levels

- Code 1: No Received Data - Open circuit, cut wire, or completely disconnected

- Code 2: CAN_H Short to Ground - High wire touching chassis/ground (reads 0V instead of 3.5V)

- Code 3: CAN_L Short to Ground - Low wire touching ground (reads 0V instead of 1.5V)

- Code 4: Transmission Error - Wires shorted together, or something jamming the bus

- Code 5: Termination Error - Wrong resistance (missing 120Ω resistor or extra one added)

Plain English. No oscilloscope interpretation needed.

Real-Time Voltage Display (Replaces Your Oscilloscope)

The screen shows you exact voltage readings in millivolts:

Recessive (Idle) Screen: Shows CAN_H and CAN_L when bus is quiet

- ✅ Normal: Both ~2500mV (2.5V)

- ❌ Bad: One reads 0mV = shorted to ground

- ❌ Bad: One reads 12000mV = shorted to battery

Dominant (Active) Screen: Shows voltages during transmission

- ✅ Normal: H=~2600mV, L=~800mV

- ❌ Bad: Both same voltage = wires shorted together ("mirror waveform")

- ❌ Bad: One stuck at wrong level = damaged transceiver or connector

You get oscilloscope-level diagnosis without interpreting waveforms.

How It Finds Partially Damaged Wires:

🔍 The "99% Chewed Wire" Problem

Rodents rarely bite completely through—they chew the insulation and leave copper strands barely hanging on. The wire shows continuity when static but fails when the car is running.

This tester catches it because:

✅ Sends 100 data packets every 2 seconds at actual CAN bus speeds (not slow DC continuity like a multimeter)

✅ Packet Counter on screen: Transmitted vs. Received

- Normal: T:100, R:100

- Partial damage: T:100, R:87 (13 packets lost = intermittent contact)

✅ Error Counter: Every failed transmission is logged

✅ Sent Data Fails: Shows exactly how many times the signal couldn't be transmitted

Real-Time Wiggle Testing:

Leave the tester connected and power on. Now wiggle suspect connectors, flex door harnesses, or tap on wire bundles while watching:

- 4 Status LEDs - Instant visual feedback (red flash = fault detected)

- Error Counter - Jumps the moment you hit the bad spot

- Voltage Readings - Spikes when corroded pins lose contact

- Audible Chirp - Confirms when good packets get through

When you wiggle the bad connector, you'll see the exact moment it fails.

Resistance Testing Without a Multimeter:

With power OFF, the tester automatically measures bus impedance:

- ✅ Normal: ~60Ω (two 120Ω terminators in parallel)

- ❌ Missing terminator: Reads ~120Ω or higher → Code 5 error

- ❌ Extra terminator: Reads ~40Ω → Code 5 error

- ❌ Wire-to-wire short: Reads very low (under 20Ω) → Code 4 error

- ❌ Corroded connector: Resistance fluctuates as you wiggle

The screen tells you what's wrong—no need to interpret ohm readings.

Two-Tester Mode: Pinpoint Exact Fault Location

Use two testers to isolate problems in long harnesses:

Example: Finding a hidden short in a 20-foot harness

- Connect Tester A at the OBD-II port (front of vehicle)

- Connect Tester B at the rear module (trunk/tailgate)

- Both show Code 4 (Transmission Error) = problem exists somewhere

- Disconnect middle connector

- Tester A now shows Code 0 (All Pass)

- Tester B still shows Code 4 = fault is in the rear half

- Move Tester A to middle connector

- Repeat until you narrow it to a specific 2-foot section

The testers "talk" to each other—when Tester A sends data, Tester B receives it and chirps. If the chirp stops, you've isolated the break.

Key Features:

✅ Super Bright OLED Display - 6 information screens (press DISP button to cycle):

- Error codes with plain-English descriptions

- Packet transmitted/received/error counts

- Recessive voltage (idle state)

- Dominant voltage (active state)

- Data transmission failure log

- Beep settings

✅ 4 Status LEDs:

- 🟢 Green = No errors detected, communication working

- 🟡 Yellow = Single tester mode (no second unit), but wiring OK

- 🔴 Red = Fault detected RIGHT NOW

✅ Data Transmission LEDs (at network connector):

- Red = Transmitting data

- Green = Receiving data

- Yellow = Transceiver powered

✅ Audible Chirp - Short beep when valid packets received (confirms good communication)

✅ Built-in 120Ω Termination - Switch it ON or OFF depending on test setup

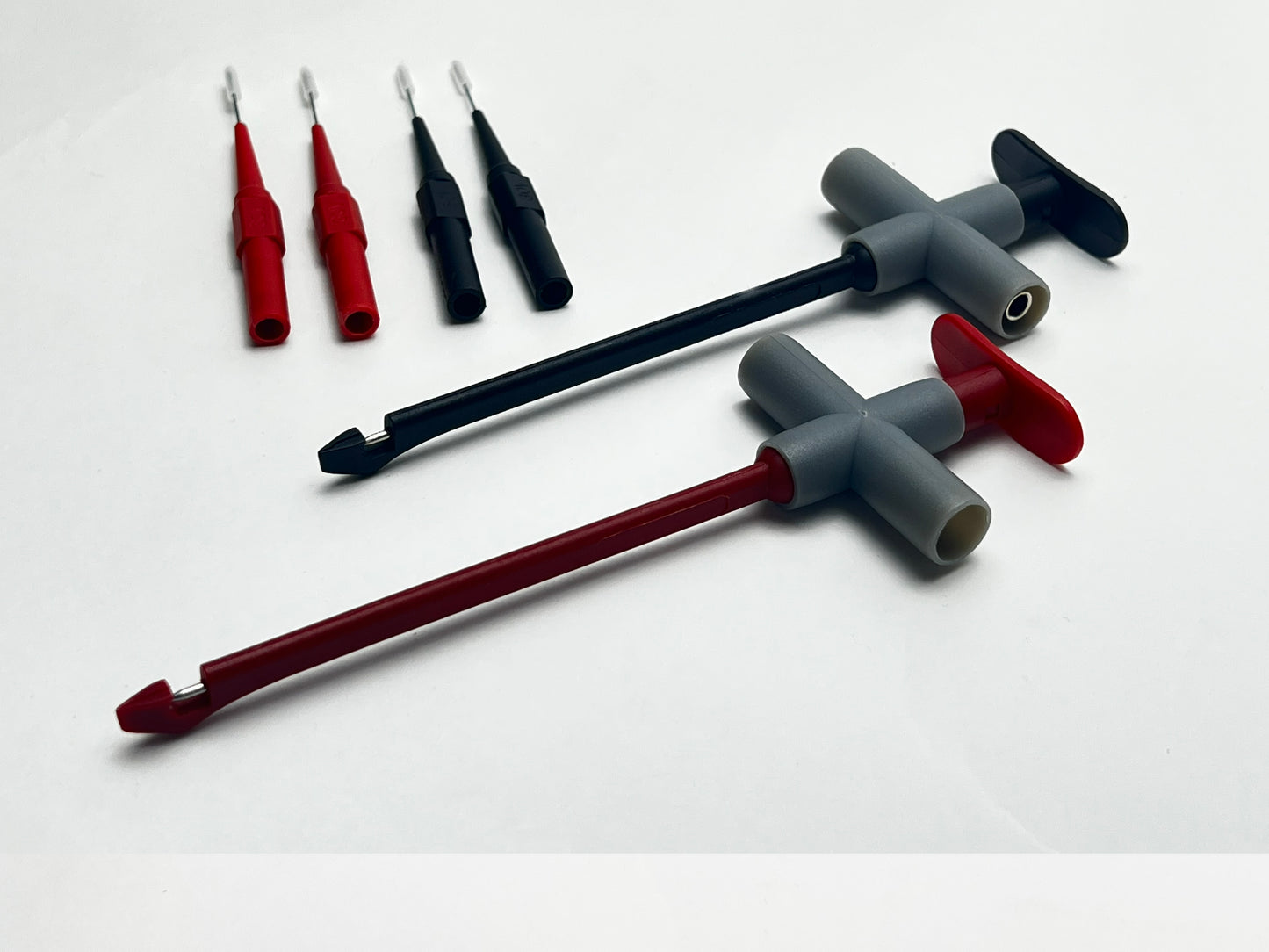

✅ Dual Connection Methods:

- RJ-45 connector (pins 4=CAN_H, 5=CAN_L) - plug into network cable

- Banana jack terminals (red/black) - clip directly onto bare wires

✅ Battery Powered - 3 hours continuous runtime, recharges via USB in 40 minutes

What You Can Diagnose in Minutes:

🔧 Connector Corrosion - Fretting corrosion creates high resistance. Screen shows voltage drop or fluctuating readings.

🔧 Partial Wire Breaks - Strands broken inside insulation. Packet counter shows loss. Wiggle test confirms location.

🔧 Shorted Wires - Mouse chewed through and CAN_H touches CAN_L. Code 4 + mirror voltages on screen.

🔧 Ground Shorts - Wire rubbed through on metal edge. Code 2 or 3 + 0mV reading.

🔧 Termination Problems - Missing resistor in module or extra one added by mistake. Code 5 error.

🔧 Bad Splices - Aftermarket alarm/remote start taps oxidized. Intermittent errors during wiggle test.

🔧 Module vs Wire - Disconnect suspected module. If error clears = bad module. If error stays = bad wire.

Who This Is For:

✔️ Technicians who need to prove it's the wiring before tearing apart interiors

✔️ Mobile mechanics diagnosing in parking lots without shop equipment

✔️ Fleet maintenance quickly testing work truck upfits and trailer wiring

✔️ DIY owners fixing their own vehicles without $3,000 oscilloscopes

✔️ Auto electricians specializing in aftermarket installs and wiring repairs

Specifications:

- Displays voltage in millivolts (0-6500mV range)

- Counts transmitted, received, and error packets

- Tests standard 250kbps and 500kbps CAN networks

- Measures termination resistance (expects ~60Ω)

- Works on 12V automotive systems

- Dimensions: 3.86" × 2.52" × 1.03" (98 × 64 × 36mm)

- Weight: 0.62 lb (260g)

The Bottom Line:

This tester gives you oscilloscope-level wire diagnosis in a tool as simple as a test light. No training required—just plug in, read the screen, and fix the actual problem instead of guessing.